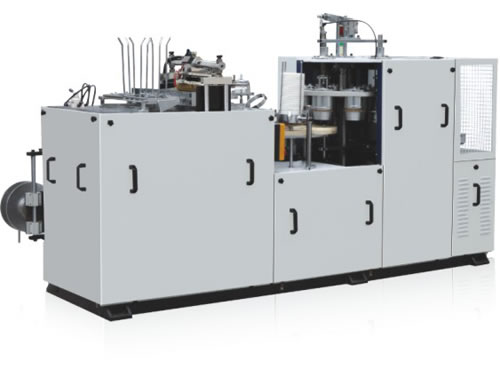

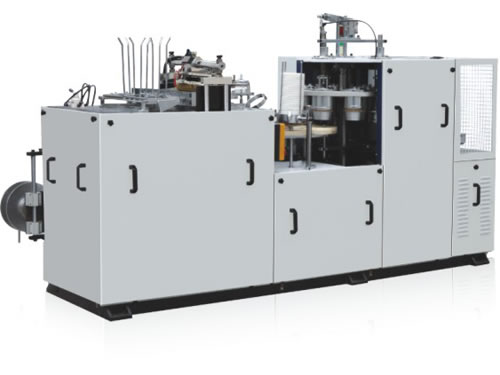

MB-S35 Ultrasonic Double PE Coated Paper Bowl Machine

Description

Ultrasonic double PE coated paper bowl machine (ultrasonic double PE coated paper bowl forming machine) is mainly used for manufacturing single or double PE coated paper bowls after running a set of procedures (automatic printed-fan-shape-paper feeding, two-step pre-heating, bowl-side-body sealing, silicone oil lubricating, bottom punching, two-step bottom heating, bottom pre-folding, bottom knurling, top rolling and paper bowl collection). This ultrasonic paper bowl machine is an ideal device for making paper soup bowls, noodle bowls, large food containers, and so on. The main parts of this double PE coated paper bowl forming machine consists of Maanshan steel (triangle iron, channel steel) sprocket, chain, rod, cam, bearing, gearbox, motor, automatic speed control inverter, CHNT components, etc. Our company makes uses of wooden cases for sea transportation.

Features

1. The ultrasonic paper bowl machine enjoys photoelectric detection, fault alarm, counting and other functions to ensure better mechanical efficiency.

2. MB-S35 ultrasonic double PE coated paper bowl forming machine has passed tensile testing and dynamic balancing test, which ensures stability of the mechanical operation.

3. This paper bowl making machine utilizes imported ultrasonic system. They will not damage the printing on the paper bowl, thus make paper bowls with a neat and smooth surface.

4. The ultrasonic paper bowl machine features easy operation, stable performance, occupying little area and high efficiency. When this equipment is working, it is forbidden to be close to it.

5. Mingbo ultrasonic double PE coated paper bowl forming machine is installed with a micro-computer controlled inverter. It helps the equipment realize speed regulation.

6. Photoelectric tracing system is used in this type of equipment.

7. The optically controlled non-contact switch automatically controls this ultrasonic paper bowl machine and ensures the safety of the machine and operator.

8. Our double PE coated paper bowl forming machine features cheap operating cost and low investment.

9. It is equipped with air-suction paper feeding mechanism, container wall forming, adhering and knurling and paper-lip forming.

10. This range of ultrasonic paper bowl machine is certified by CE approval.

Maintenance

The mechanical moving parts of the ultrasonic double PE coated paper bowl forming machine should be added some engine oil every day, while butter-grease every 15 days. All screws and chains must be checked carefully and locked tightly. We should pay attention to the sanitation and cleanliness of the paper bowl making machine. Keep greasy dirt away from the paper, die and roller. This ultrasonic paper bowl machine should be located away from paper scraps, dust accumulation or plastic rolling.

Parameters of MB-S35 Ultrasonic Double PE Coated Paper Bowl Forming Machine

| Specification | 20 to 35 oz(mould could be changed to different sizes), height up to 125 mm |

| Paper Material | 140 to 380 gsm, Single PE Coated Paper |

| Production Speed | 35 to 40 pcs/m |

| Power Supply | 380 V, 50Hz |

| Total Power | 9 Kw |

| Weight | 2500 kg |

| Overall Dimension | 2800 mm × 1200 mm × 1600 mm |

| Air Source | 0.6 Mpa, 0.6 cbm/min |

Note: We can produce special sizes of ultrasonic paper bowl machines according to customers' requests.

- MB-D35 Automatic Single PE Coated Paper Bowl MachineAutomatic single PE coated paper bowl machine or automatic single PE coated paper bowl forming machine is an automatic machine with multi-working station, which has functions of photocell detection, failure alarm, counting and the advantages of humanism design, safer operation and easier maintenance. This paper bowl making ...

Automatic Paper Bowl Making Machine

Automatic Paper Bowl Making Machine Paper Bowl Forming Machine

Paper Bowl Forming Machine Paper Bowl Making Machine

Paper Bowl Making Machine